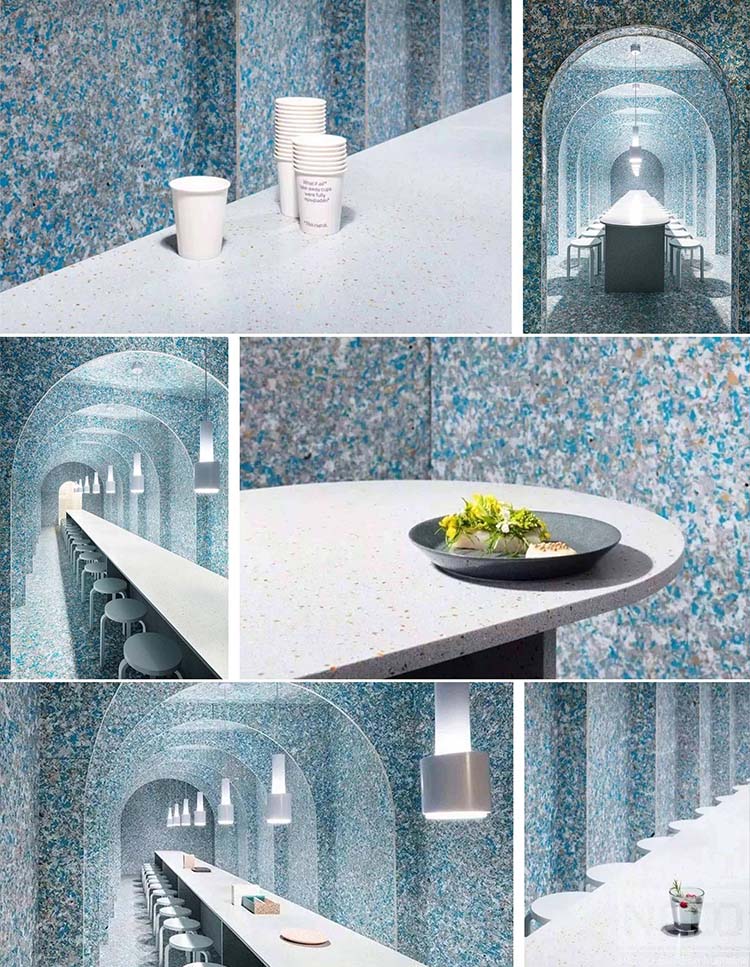

Combination of Terrazzo and Glass Aggregate

Combination of Terrazzo and Glass Aggregate

In today's environment of advocating green environmental protection, all walks of life are pursuing materials that can meet national policies. Low operating costs, health and pollution-free, strong durability and low maintenance costs are the hallmarks of today's green ground projects. Often the task of the designer is to choose flooring materials that are attractive and easy to maintain, and can last for many years.

When we talk to many designers, they ask what materials are available to achieve their environmental goals, and we usually advise them to choose inorganic terrazzo.

丨The application of inorganic terrazzo in today's environmentally friendly ground

Inorganic terrazzo, a combination of marble chips and cement, has led the way in the application of flooring systems for centuries. This is because in the 15th century, Venetian builders reused waste to build cheap ground in their living quarters.

Inorganic terrazzo is suitable for those seeking efficient ground systems, and in terms of its overall appearance and contribution to environmental certification, inorganic terrazzo is the most suitable material.

In today's green building era, the use of inorganic terrazzo floor is very common, compared with marble, PVC wood board and other floor materials, inorganic terrazzo system non-toxic, odorless, non-flammable characteristics can be more recognized by customers.

丨Optional glass aggregate for inorganic terrazzo

The reason why terrazzo is bright as a mirror and crystal clear is mainly because terrazzo forms a glass film on the surface after mechanical processing, which not only has a mirror luster, but also can transparently show the inner structural level of the stone, that is, the pattern pattern that people observe, and the bright beauty is here. The key to restoring the beauty of weathered and abrasive terrazzo is to re-form a vitreous film on the surface of the terrazzo.

There are a variety of glass aggregates to consider in inorganic terrazzo floor designs, including mirror glass, flat glass, stained glass, cobalt blue glass, tan glass, and green glass.

Here are the glass options available and each one that a design should be aware of:

Clear glass

Clear glass shards can be combined with any color to keep the floor clean and tidy.

Mirror glass

Mirror glass is favored by designers, and mirror glass fragments can reflect sunlight and make the ground look shiny.

Inorganic terrazzo aggregate is far more than a variety of glass, such as marble, shells, etc. are also commonly used aggregates, we will introduce you to more choices of inorganic terrazzo aggregates in the next issue.

How to Choose A Good Rammed Earth Board?

The rammed earth board is prefabricated in the factory, and it can be directly mounted on the site. Designers who like everything can be prefabricated should come over.

The Three Indicators of Concrete Include

As a commonly used building material circulating in the construction industry today, it is common to hear about the three main indicators of concrete to meet design requirements. So, what are the three main indicators of concrete?

FAQ

FAQ about Nicoo Concrete

Raw stone - Inorganic artificial travertine stone

Artificial stone since its birth, after decades of development, has long been one of the mature decorative materials on the market, now more than 90% of the industry is resin artificial stone products, artificial stone is the future trend of inorganic artificial stone.