UHPC Performance Upgrade and Industry Application

UHPC Performance Upgrade and Industry Application

What is UHPC?

UHPC (Ultra-High Performance Concrete) is a special concrete with super high strength, super low water absorption, super durability and erosion resistance. At present, the compressive strength of UHPC used in the field of architectural design (different from the structural field) is greater than 120Mpa and the flexural strength is greater than 15Mpa. Although UHPC can achieve high compressive strength, UHPC is mainly used for thin building components. flexural strength. In practical applications, the ultra-high strength of the UHPC matrix is further reinforced and toughened by a small amount of alkali-resistant glass fiber, synthetic fiber, and metal fiber.

UHPC belongs to a new type of polymer material, which uses concrete as the most basic cementing agent, and then combines various fiber-mixed materials, water-reducing agents, etc. to form a cementitious material polymerization. material. Among many construction and decoration materials, the application of concrete is increasing year by year. Compared with traditional decoration materials, it has better corrosion resistance and durability.

Performance and industry application of UHPC

1. In the offshore oil service industry, uhpc can be used to increase the thickness of the outer protective layer of the steel frame structure of the oil service platform, and enhance the support for the water level changing area.

2. The development trend of uhpc is relatively fast, and the compressive strength is increasing year by year. It has more applications in reinforcement and repair engineering projects, and is more conducive to cost control in the production process of enterprises.

3. Compared with traditional concrete, the impact resistance of uhpc has been greatly improved, and it has more applications in the construction of national defense and security engineering projects.

4. The high density of UHPC has been better improved, and the smoothness of the parts in contact with the production mold has been greatly improved. It is difficult for some external harmful substances to enter into UHPC, and the substances contained in it are difficult to enter. Additives and other ingredients are not easy to dissolve outwards, so they are often used in outdoor building materials.

The UHPC structure is relatively lightweight, and no additional reinforcement is required for support during the application process, which greatly extends the use span and greatly improves innovation. In addition, compared with traditional materials, its corrosion resistance, carbonization resistance and penetration resistance of harmful substances have also been well improved, and it has excellent waterproof effect, which can help many designers to better The realization of the dream that traditional materials cannot help it accomplish.

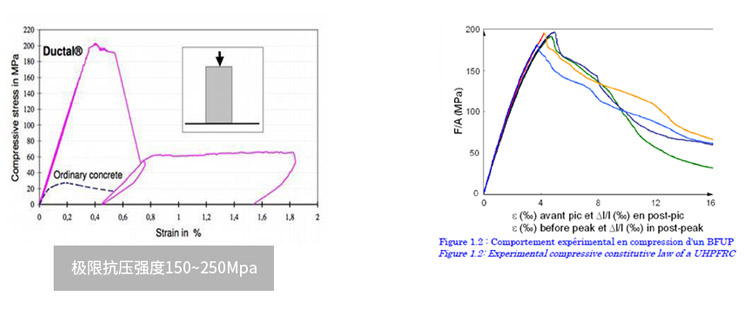

Mechanical Properties

Simple ultra-high compressive strength is often accompanied by "ultra-high brittleness", which does not mean "ultra-high performance". The "ultra-high mechanical properties" of ultra-high performance concrete (UHPC) are mainly reflected in ultra-high tensile strength (uniaxial tensile and flexural tensile strength) and high toughness.

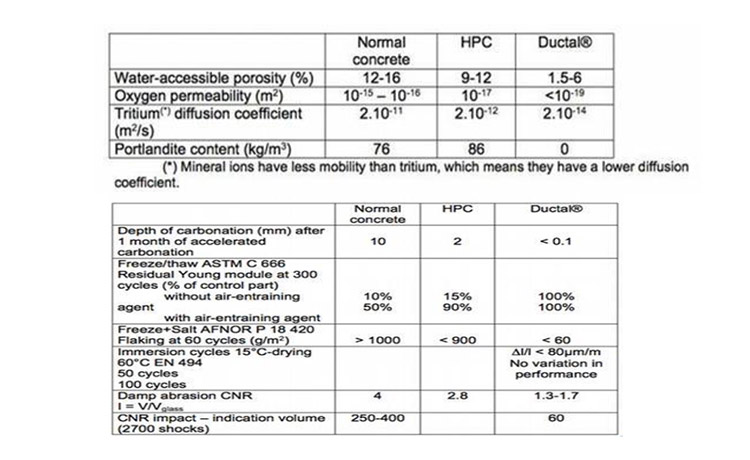

UHPC Durability

Another most attractive property of ultra-high performance concrete (UHPC) is the potential for ultra-high durability. According to the theoretical and experimental research results, it can be basically confirmed that: UHPC has no problems of freeze-thaw cycle, alkali-aggregate reaction (AAR) and delayed ettringite formation (DEF) damage; Compared with traditional high-strength and high-performance concrete (HSC/HPC), the durability performance indicators such as chloride ion intrusion, sulfate corrosion resistance, chemical corrosion resistance, and wear resistance are improved by orders of magnitude or multiples.

What is the difference between fair faced concrete and ordinary hanging board

At present, it is difficult to distinguish the authenticity and variety of panels on the building materials market, so today we will talk about the difference between fair-faced concrete board and ordinary board.

NICOO 2020 New Product Translucent Concrete

Translucent concrete is one of NICOO's flagship products in 2020. Combined with various customized products, it will bring more new ideas and creations to customers.

Designer Recommended Vintage Wood Grain Concrete Board

Suitable for chain stores, hotel clubs, art galleries, homestays, Internet celebrity shops, villas, etc. Wood grain board natural wood grain. Natural calm, texture can be deep or shallow, thickness can be customized. Wet stick dry hanging can be, the back can be done back bolt, installation is also very convenient.

The Application of Liquid Marble

Learn about 3D art marble. With the development of science and the progress of technology, stone processing technology is diverse, stone crafts have broken through our inherent imagination. You do not expect that the hard natural marble has become so soft and romantic.